Separator AWAS SK

High flow systems

Description of large catchments:

- very high and irregular flows,

- high quantities of sludge and suspended matter,

- small quantities of oils,

- possibility of oil failures.

SK 10/100 Separator was tested by a TÜV Rheinland notified body and passed the test as the only coalescence separator with bypass in Europe. It is the only separator meeting all the requirements of PN-EN-858-1 for separators with internal bypass; this is confirmed with a certificate for AWAS.

In the case of bypass separators all requirements of PN-EN-858-1 must be met for the nominal size of the separator.

Effectiveness of treatment

The separators comply with the regulation of the Minister of Environment of 24.07.2006 Journal of Laws No. 137 item 984 as amended, concerning the conditions that should be met for introducing waste into waters or ground and for substances that present a special hazard to the water environment.

In Europe the effectiveness of treatment is checked using guidelines of the standard 858-1. For bypass separators the checks include:

• the efficiency of oil separation at the nominal separator flow for 45 minutes,

• washing out of the accumulated oils during maximum flow rates.

Sludge separation effectiveness

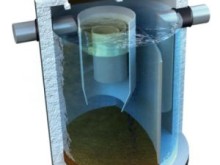

The tests performed by TÜV Rheinland have shown that the spiral installed in the hydrocyclone makes the route of flow up to 10x longer compared to other separators and hence the time of waste lagooning is lengthened. Due to that the effectiveness of separation of hard settling suspension (not stopped in the sedimentation tank before the separator) is higher. Effectiveness this high enables using a 50% smaller sedimentation tank chamber than the one required by 858-1 standard (TÜV certificate).

Treatment of precipitation sewage from hardened surfaces subjected to minor oil pollution with significant content of suspensions requires the use of a sedimentation tank upstream from the separator in spite of a separate sedimentation chamber in an SK separator. The integratedspiral enables decreasing the sedimentation area of the separator by half compared to the one required by PN-EN-858-1 (tests and TÜV certificate). Due to the fact that the filterless circulation-coalescence separator does not have any moving, replaceable or removable parts, it prevents secondary terrain contamination during the cleaning of separators with removable lamella or filter inserts. It can be cleaned from an emergency lane or from a special road bay for service vehicle. The optimum distance between a device and the edge of the road is 30m. If the distance exceeds 30m (but is not more than 100m), servicing requires special equipment that enables draining from longer distances. This makes servicing more expensive but costs are still lower in comparison with the costs of construction and use of an access road used only twice a year.

Treatment of precipitation sewage from hardened surfaces subjected to minor oil pollution with significant content of suspensions requires the use of a sedimentation tank upstream from the separator in spite of a separate sedimentation chamber in an SK separator. The integratedspiral enables decreasing the sedimentation area of the separator by half compared to the one required by PN-EN-858-1 (tests and TÜV certificate). Due to the fact that the filterless circulation-coalescence separator does not have any moving, replaceable or removable parts, it prevents secondary terrain contamination during the cleaning of separators with removable lamella or filter inserts. It can be cleaned from an emergency lane or from a special road bay for service vehicle. The optimum distance between a device and the edge of the road is 30m. If the distance exceeds 30m (but is not more than 100m), servicing requires special equipment that enables draining from longer distances. This makes servicing more expensive but costs are still lower in comparison with the costs of construction and use of an access road used only twice a year.

Treatment of precipitation sewage from hardened surfaces subjected to minor oil pollution with significant content of suspensions requires the use of a sedimentation tank upstream from the separator in spite of a separate sedimentation chamber in an SK separator. The integratedspiral enables decreasing the sedimentation area of the separator by half compared to the one required by PN-EN-858-1 (tests and TÜV certificate). Due to the fact that the filterless circulation-coalescence separator does not have any moving, replaceable or removable parts it prevents secondary terrain contamination during the cleaning of separators with removable lamella or filter inserts. Also, special equipment is not required for draining from longer distances. It can be cleaned from an emergency lane or from a special road bay for service vehicle. The optimum distance between a device and the edge of the road is 30m. If the distance exceeds 30m (but is not more than 100m), servicing requires special equipment that enables draining from longer distances. This makes servicing more expensive but costs are still lower in comparison with the costs of construction and use of an access road used only twice a year.

Treatment of precipitation sewage from hardened surfaces subjected to minor oil pollution with significant content of suspensions requires the use of a sedimentation tank upstream from the separator in spite of a separate sedimentation chamber in an SK separator. The integratedspiral enables decreasing the sedimentation area of the separator by half compared to the one required by PN-EN-858-1 (tests and TÜV certificate). Due to the fact that the filterless circulation-coalescence separator does not have any moving, replaceable or removable parts it prevents secondary terrain contamination during the cleaning of separators with removable lamella or filter inserts. Also, special equipment is not required for draining from longer distances. It can be cleaned from an emergency lane or from a special road bay for service vehicle. The optimum distance between a device and the edge of the road is 30m. If the distance exceeds 30m (but is not more than 100m), servicing requires special equipment that enables draining from longer distances. This makes servicing more expensive but costs are still lower in comparison with the costs of construction and use of an access road used only twice a year.

The design of separators is resistant to terrain deformations and mining damage. To protect sewage receivers against emergency drains it is recommended to equip the separator with an alarm device to signal overfilling with oil substances and to install a closing device on the separator’s outlet (only for SK 100 and SK 200).

New:It is possible to select additional oil containers according to the requirements of an investment.

Description of large catchments:

- High effectiveness of oil and suspension separation.

- Filterless coalescence – no moving and replaceable parts.

- Compact monolithic design (for 10/100, 20/200, 40/400. 60/600).

- Modern treatment technology using circulating movement, longer route and flow time.

- Reliability and safety – water traps at inlet and outlet.

- High storage volumes.

- Oil tank and its volume can be adapted for the requirements of the investment. Thanks to the correct design of the funnel of the separator located in the hydrocyclone, oil flows to the tank. The stored petroleum derivatives are safe and protected against washing out.

- Closing in hydrocyclone. A closing device can be fitted in a hydrocyclone to assure that the separated oils will not leave the collection area in the case of an uncontrolled supply of oils into separators when it will not be possible to collect them in an oil tank.

- Closing device at the outlet. Separators SK 10/100, 20/200 can be fitted with a float outlet closure. Separators SK 40/400, 60/600 can befitted with a ball outlet closure.

- Alarm system. A probe to warn about critical level of oils can be installed in a tank or in a hydrocyclone.